Air Quality

Managing Air Quality in South Africa

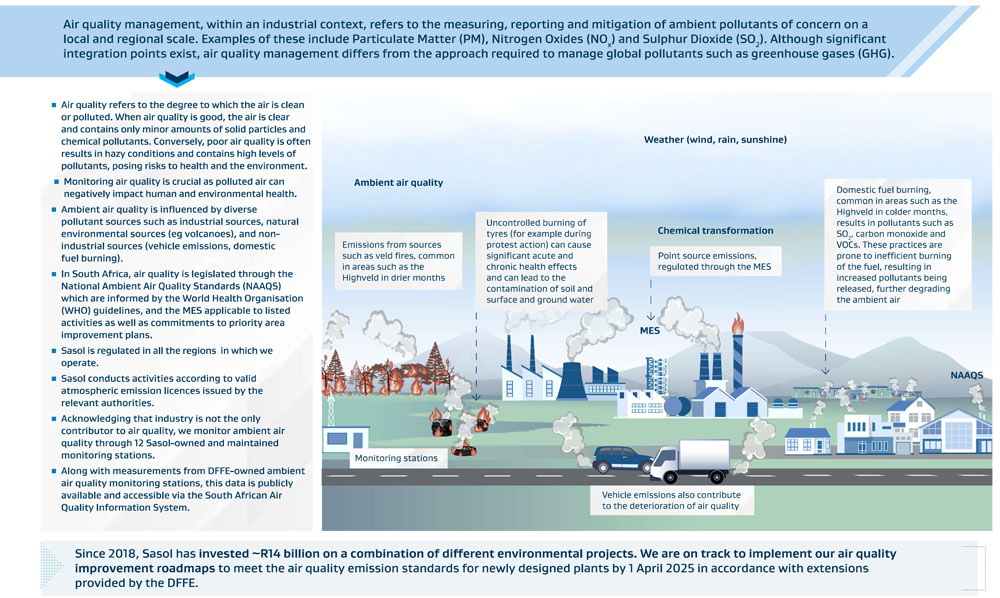

Over the years, we have continued our efforts to reduce our impact on air quality. These are focused on compliance with regulatory requirements to retain our licence to operate; innovative solutions; and constructive engagements with stakeholders including our fence line communities and regulatory authorities.

Why this is a Material Matter

- All employees and service providers must go home safely each day.

- We remain committed to ensuring a safer workplace for all and Zero Harm.

|

Help

|

Hinder

|

||

| Group strategic priority: Zero Harm ambition | |||

| Impact of Material Matter | Opportunities | Mitigation actions | Metrics Short term Medium term Long term |

|

|

|

|

|

Risk Short term - Safety, Health and Environment |

|||

Why this is a Material Matter

- By embracing agility, Sasol will remain robust and capable of navigating the complexities and challenges of the changing energy landscape. This will contribute to building a sustainable Sasol which is profitable and adaptable in the future.

- As part of our strategic ambition to “strengthen our foundation”, we aim to enhance delivery and maximise free cash flow generation to strengthen the balance sheet.

|

Help

|

Hinder

|

||

| Group strategic priority: Zero harm ambition | Strengthen our foundation business | Build an empowering culture | Progress grow and transform agenda | |||

| Impact of Material Matter | Opportunities | Mitigation actions | Metrics Short term Medium term Long term |

|

|

|

|

|

Risk Short term - Safety, Health and Environment |

|||

Why this is a Material Matter

- We are committed to unlocking full value and building a more sustainable business through a balanced and measured approach—transforming our business responsibly by ensuring ongoing value creation across all stakeholder groups.

|

Help

|

Hinder

|

||

| Group strategic priority: Progress grow and transform agenda | Deliver stakeholder value | |||

| Impact of Material Matter | Opportunities | Mitigation actions | Metrics Short term Medium term Long term |

|

|

|

|

|

Risk Short term - Financial Short to long term – Strategy Execution, Climate and Sustainability |

|||

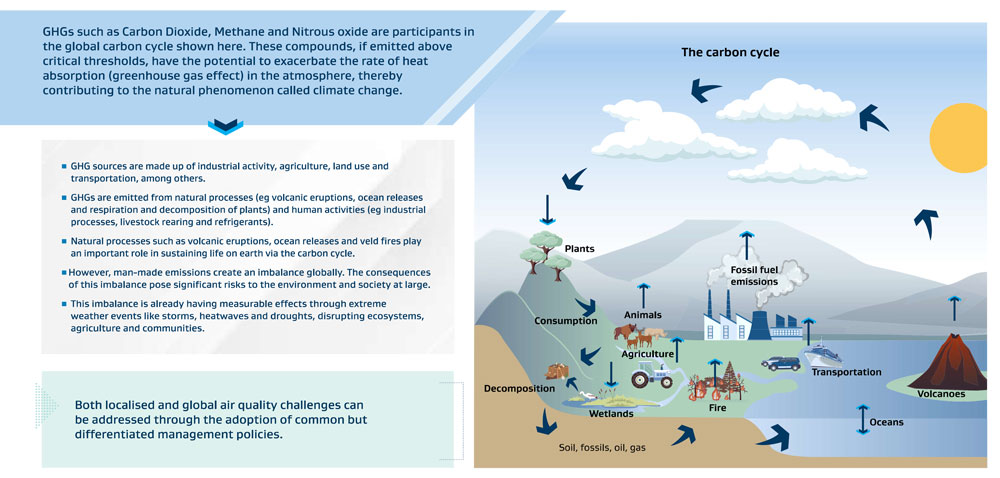

Why this is a Material Matter

- We need to operate within the regulatory and policy framework to maintain our licence to operate.

- Building a strong foundation to reduce GHG emissions and carbon intensity.

|

Help

|

Hinder

|

||

| Group strategic priority: Progress grow and transform agenda | Deliver stakeholder value | |||

| Impact of Material Matter | Opportunities | Mitigation actions | Metrics Short term Medium term Long term |

|

|

|

|

|

Risk Short term - Safety, Health and Environment |

|||

Why this is a Material Matter

- Strengthening relationships with all our stakeholders is essential to building credibility and trust.

- Being perceived as a credible partner will contribute to effective delivery and the creation of shared value.

|

Help

|

Hinder

|

||

| Group strategic priority: Progress grow and transform agenda | Deliver stakeholder value | |||

| Impact of Material Matter | Opportunities | Mitigation actions | Metrics Short term Medium term Long term |

|

|

|

|

|

Risk Short and medium term - Stakeholder and reputation |

|||

We are committed to implementing the second phase of our offsetting implementation plan which is focused on the reduction of PM and SO2 pollution in the surrounding communities. The plan includes a comprehensive education and awareness campaign, covering the public and schools. The school awareness campaign consisted of nine secondary schools within the communities of Govan Mbeki Local Municipality. The campaign created a positive impact as learners were introduced to in- depth concepts of air quality. Engagements sessions and door-to-door campaigns that were conducted, exceeded 7500 households in Embalenhle and Lebohang since the inception of the campaign. The impact of the programme was bolstered by the publication of these relevant topics, in local newspapers, in three regional languages. Between 2017 and 2020, we implemented the retrofitting of thermal insulation to houses and a LPG for coal stove swop in 5532 households across eMbalenhle and Lebohang to reduce emissions from coal burning, while simultaneously improving the quality of life participating households. The evaluation of the household intervention was conducted in 2023 during the Phase 2 Re-baseline Air Quality Offsetting Campaign study of which 507 retrofitted households participated. 97% of the retrofitted households remain coal free. Additionally, 200 houses were retrofitted in eMbalenhle during the Phase 2 household intervention offsetting project. Sasolburg’s offset programme continues to contribute to air quality improvement. The paving of the original 1.6 km road in Zamdela assisted in limiting dust liberation due to vehicles travelling on the road. Approximately 5 000 ton of PM10 and 1 300 ton of PM2.5 emissions per year were reduced. An additional 1.8 km of road in the same area has been paved during the reporting period and the associated reduction impact will be assessed during 2025. Sasolburg and Natref cut about 3.6 million m2 of grass and removed some 900 ton of biomass around the Sasolburg area. Approximately 6 tons of PM10, 5 tons of PM2.5 and 1 ton of SO2 emissions were avoided due to this intervention. Furthermore, around 2 740 tons of domestic waste was removed resulting in approximately 20 tons of PM10, 19 tons of PM2.5 and 3 tons of SO2 emissions being avoided.

Sasolburg’s longer-term planning includes the role out of low smoke coal stoves within the Zamdela area to households making use of open fires for heat and cooking purposes. A pilot project was launched where 50 stoves were tested within a community in Oranjeville. Promising results, with an 80% reduction in emissions compared to conventional stoves have been observed. The next phase is to commercialise the stove where after construction and a larger role out will commence. The Education and Awareness program within the Zamdela area was a success with 10 100 learners and 80 teachers reached through this program. The program entailed inter alia an informative puppet show for lower grades and an industrial theatre for higher grades.

The vehicle emission testing program which has been re-established and weekly monitoring of vehicle emissions has commenced.

Improvements for Particulate Matter reduction within Secunda, Sasolburg and Natref Operations include:

- At Secunda Operations, we have retrofitted 16 out of 17 ESPs with abatement equipment and

- At Sasolburg’s Steam Station plants, we upgraded eight of the 12 ESPs with one boiler being retrofitted at our Steam Station 1 plant

Improvements for Nitrogen Oxide reduction within Secunda, Sasolburg and Natref Operations include:

- Three additional low NOx retrofits at our boiler fleet were completed during the reporting year at SO with a fourth installation ongoing, with the roll-out of the remainder of the fleet on track to be fully compliant with the MES limit. A total of 9 boilers were retrofitted with low NOx burner abatement technology up to date.

- At SEO, low NOx burners were installed on seven of the 12 operational boilers, with one low NOx burner installation currently in progress.

Improvements reduction from our incinerators within Secunda and Sasolburg:

- The Bio-sludge to gasification project is now in construction phase with eight reactors (part of the Cambi lysis units) installed up to date. This project will enable carbon beneficiation from this waste stream that is currently incinerated in the bio-sludge incinerators, enabling the decommissioning of the bio- sludge incinerators

- At Sasolburg, we continue to review the sustainable alternative method to incineration for the handling of the Sasolburg waste streams

SASOLBURG OPERATIONS AELs

W&S FDDM MET 2013 20 R2

Midland FDDM MET 2013 24 R2

GT FDDM MET 2013 18 R2

LOC FDDM MET 2013 22 R2

GLUC FDDM MET 2013 23 P3 R1

2025 03 24 Natref AEL

2022 06 NDO Prospecton AEL

2022 06 NDO Fynnland Site 1 AEL

2022 03 NDO Fynnland Site 2 AEL

SECUNDA OPERATIONS AELs

1 Secunda Operations Synfuels, with reference number 0016/2025/F04.

2.2 Secunda tank farm and loading, with reference number 0018/2025/F04.

2.3 Secunda Operations Solvents, with reference number 0017/2025/F04.

2.4 Secunda Operations Polymers, with reference number 0021/2025/F04

2.5 Secunda Operations Nitro fertilizers, with reference number 0020/2025/F05

2.6 Sasol Oil (Pty) Ltd, with reference number 0019/2025/F05.

EKANDUSTRIA AELs

Atmospheric Emission License for Ekandustria - redacted